Contents

A Farewell to Manual Processes: Why You Should Ditch Them For Health and Safety

18 November 2021 - Evotix

One of the great classics in American literature is A Farewell to Arms by Ernest Hemingway. In the title, “arms” naturally means weapons, but it got us thinking about human arms—the ones attached to our bodies. Arms are attached to hands, and together they can do amazing things, such as paint pictures, design buildings, and even write blogs. But you know what arms and hands don’t need to be doing? Manual health and safety processes.

What’s wrong with health and safety manual processes? A lot of it has to do with the word “manual.” It conjures up images of grabbing a shovel and digging a ditch. Manual typewriters, manual lawnmowers, manual sewing machines, and manual eggbeaters—why use them if you don’t have to? There are machines and technology out there now that make those things easier. Think about how you do everyday tasks: open an app on your phone and you can almost instantly start ordering the family dinner or managing your finances.

So, if you digitally manage every other aspect of your life or business, then why are you still using manual processes to manage your health and safety program? In this blog, we explain why you should say goodbye to manual health and safety processes and say hello to health and safety technology.

Manual processes kill employee engagement

Collecting data is a key part of any successful health and safety program, and to get that data you need to have engaged employees. Although you can’t demand that employees participate and expect to be successful, you can encourage them to by eliminating barriers or reasons for them to not engage. “My favorite thing about filling out forms is how easy they make it to engage with health and safety,” said no one in your business ever—so that’s where you should start your engagement journey.

Put yourself in the shoes of your workforce – how easy is it for them to report an incident, hazard or near-miss? After they’ve been involved in any of those events, do they have to walk to your head office to retrieve a form, go somewhere to fill it out, and take it back to your head office? Although that process might have made sense at one time, it’s not right for modern workers. They need an easily accessible way to report safety observations and incidents in real-time—as they’re happening.

EHS software can break down those engagement barriers. It offers intuitive online and offline forms for easily logging environment, health, safety, security and quality incidents against a predefined set of criteria. This helps collect information so that it aligns with relevant regulations. Your health and safety team, HR, or anyone else you designate can automatically pick up and escalate the incident. A comprehensive software system can offer flexible and dynamic data collection and management to help you respond rapidly to new standards and regulations in reporting.

Manual processes put health and safety in a black hole

Health and safety data flows into your business at a volume and rate that is continually on the increase. Some of that data might still be in paper files or documents. Some of it might be generated from sensors installed on equipment. And some of it might be coming in from mobile devices. So, where is it landing? The answer is that workers on your health and safety team are probably manually inputting it into spreadsheets—lots of spreadsheets. Do you know where all the spreadsheets are? Does anyone?

Spreadsheets can make your health and safety organization feel “safe.” Your business has created them for itself and that seems to be a fair tradeoff for what appear to be a few limitations. Eventually these safety nets can break, though. Duplicate data, data lost on a hard drive, mistakes in formulas… these aren’t good things. What they create is a black hole of missed opportunities for health and safety enlightenment and improvement.

In the meantime, you might have noticed that other departments in your company are using technology that generates reports on anything from sales wins and losses to employee engagement. By investing in health and safety technology, you can see the same ROI as the Finance Office does when it uses specialised reporting software. With health and safety software, you take all your health and safety data and easily visualise it so that it supports your decision-making, enabling you to enact proactive measures based on leading indicators.

Manual processes leave you flying blind

When you manually record or perform calculations on data, it’s difficult to see what it’s telling you. You can probably get a snapshot of the past, but snapshots aren’t the whole picture. You end up focusing on data that is the result of an incident or information that is outdated by the time it’s recorded. This creates lagging indicators, which only tell a part of the story, but does not always help you determine causality or identify patterns that should be addressed.

With manual processes, it’s close to impossible to track patterns and trends and uncover trends that can help you take a proactive approach to health and safety. So, people make decisions based on instinct or a “gut feel,” and not necessarily on facts or evidence. You might as well be flying blind.

Health and safety software helps your business stop guessing and start making more informed health and safety decisions. Here are some examples of what it offers:

- Trend analysis: Using real-time data visualisations and dashboards, you can spot trends or hotspots that indicate a problem. Trend analysis enables you to proactively determine if the trend is an outlier or something that needs a solution before it is too late.

- Leading indicator tracking: You pull information about incidents from your systems, create health and safety key performance indicators (KPIs), and then use the leading metrics to drive decisions about how to improve.

- Prediction and prevention. With summary reports and metrics generated by the software, you can predict where preventative interventions will be most effective.

Ready to say goodbye to manual health and safety processes?

Want to see first-hand the top 5 things that spreadsheets can't do? Click below to watch our on-demand webinar to learn more.

RELATED BLOGS

What is EHS Software? The Ultimate Guide

9 March 2022 - Evotix

The rate of workplace accidents is far too high. In fact, in some countries, it hasn’t been improving at all. Behind every one of those statistics is a name and a family – and that’s why at Evotix,..

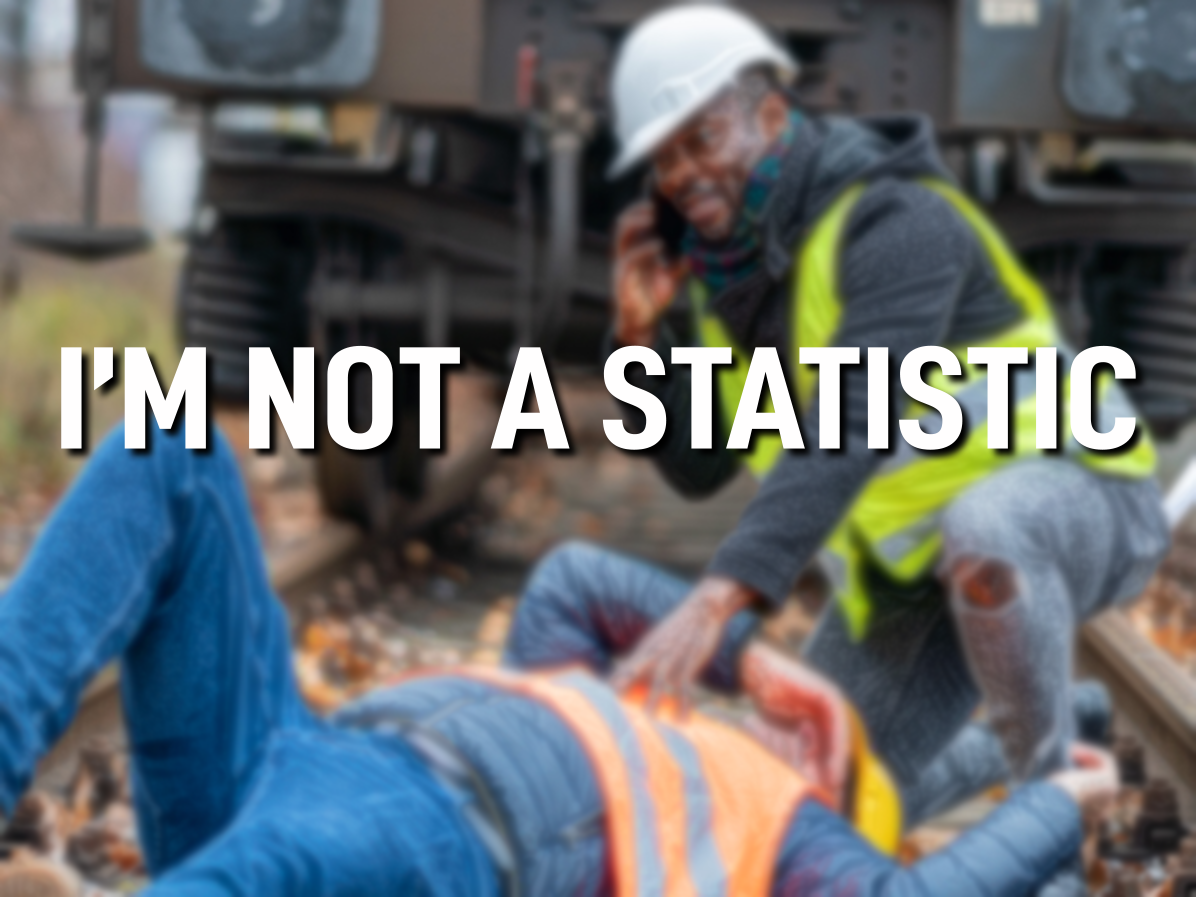

I’m Not a Statistic: Safety is Your Number One Priority? We call BS.

11 August 2022 - Evotix

As individuals, it’s likely we each have our own personal values that we live by. In business, company values are ever present, from global powerhouses such as Apple and Nike, right through to small..

How To Ensure Good Health And Safety Practices In Manufacturing

1 December 2022 - Evotix

The manufacturing industry is an economic powerhouse in the U.S. It’s responsible for producing 20 percent of the nation’s capital investment, 35 percent of productivity growth, 60 percent of..